@EricM_Inovelli – can you answer this one?

Project Update: The manufacturer is trucking along and should have the final structure design (for our approval) on April 26th. The next steps after that is for them to start laying out the PCB and PCBA which is targeted to finish on May 15th.

Our proposed implementation of how the buttons will work with association groups and bindings will be able to do this and more. It is similar to what you are saying. I haven’t received feedback from the manufacturer on it yet, but I think it will be approved. My only worry is that it may take a lot of storage space to implement, but we will see.

If the storage space is an issue, they could add a second MCU right? Similar to how the 2nd gen Red series worked? Would definitely drive cost / complexity up, but it’s probably worth it to get this done correctly.

My understanding is that, at least on the z-wave side, the 500 series chip was very constrained, and the 700/800 series are much more capable, in terms of storage and (I think?) also compute. So ![]() it won’t be an issue.

it won’t be an issue.

@EricM_Inovelli That sounds great! If I can be helpful, I’d love to help, but if you’ve got things under control I’m also happy to just stay out of the way.

Yeah, for sure. That is something we can investigate if storage space comes up as an issue. When I get initial feedback from the firmware specs I can ask. Just fitting an extra mcu will require pcb space, complexity, and cost.

@Eric_Inovelli any good news?

It’s really exciting that this project is finally nearing the finish line. At some point in the last few years, I believe I remember reading backers of the original project would be given the opportunity to order more units at the price we paid for the preorder.

Is this accurate, and if so when/how will this work?

Well, sort of lol. It’s taking a little bit longer for them to come up with a structure design, so they bumped this deadline to May 16th, but they did provide the .stp file to us and they have been 3D printing against that .stp design. They’re now working on eliminating light leakage.

Here’s the latest PM they sent me along with a very very rough 3D print:

–

Please find the latest button switch STP file as attached, including external and internal structures.

-

The STP file already contains all structures for your 3D rendering design.

-

We used a 3D printer to print the button switch structure and tested it. At present, the tactile feedback of button pressing is not very good. We are still improving the design and cannot start the tooling building yet.

-

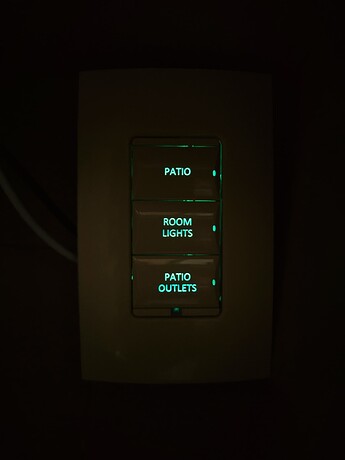

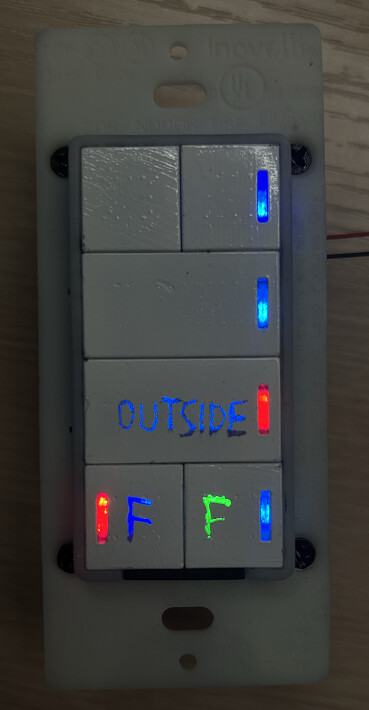

The display effect of the LED Bar and etching area has been roughly tested, as follows, and testing still needs to be continued.

-

Please review the STP design file and let us know if you have any suggestions.

-

The back size of the Button Switch is the same as that of the 2-1 switch, but the ground terminal position and internal structure are different, so the tooling cannot be shared.

-

Led bar test update, see the picture.

–

Yeah great question – I think what I’ll do is have anyone who’s interested who pre-ordered the original batch reach out to us so we can confirm it and then we’ll give you a coupon code for the newer version!

You never said Comic Sans would be an option for the button etching ![]()

Quick update posted over in the Zigbee thread: Zigbee Button Controller + Dimmer Switch | Project Walt - #143 by Eric_Inovelli

Posted this in the Zigbee thread:

Happy 4th all! What a present we received for America’s bday ![]()

![]()

Final 3D print version (notes below)

Some pictures of them testing the light leakage, which is virtually zero (3D print - see notes below)

This is the control sample we were told to test against - Control 4 version which is a $250-300 switch

A couple of videos:

Notes:

This is straight from the engineer regarding the 3D models.

Since all the plastic parts are 3D printed, the structural dimension accuracy is not enough, the surface is not smooth, and the elasticity of the lever is insufficient, resulting in some corner buttons not bouncing back in time. At present, this effect can only be achieved, and the good thing is that the gap between the buttons is reduced.

Basically saying that these are 3D prints so don’t expect it to be perfect.

Regarding the light leakage.

Eric Hines Please see the video and pictures.

- There is a phenomenon of color mixing between the backlight and the led bar, and the light of the backlight shines on the led bar, which is more obvious when the led bar is off or the brightness is low.

2.The button gap has a small part of light leakage. Reducing the brightness of the backlight can reduce these phenomena. It may also be possible to add a small number of baffles around the led bar to avoid mixing colors. We plan to send 2 inovelli samples and 2 B2B samples tomorrow, but the firmware is not perfect, there are basic dimming and OTA functions, and some backlights and led bar can be turn on by pushing buttons. You can also test button feel and light leakage. I hope you can confirm the tooling through these.

–

I’m excited to get these and move onto testing!

Thanks for the update. Is this still on track for a September release?

Probably not, unfortunately. It’s taken a ton of back and forth to get the design right. As much as I love our B2B client, they love making changes which pushes back tooling. I think we’ve finally gotten the intricacies down and can start tooling which is about a 4 week process.

From there, we need to beta test the firmware, which is about another 4-6 weeks. This one may be longer bc it’s a monster from a firmware side.

They usually submit the switch to ETL around the time beta testing kicks off since the hardware is completed and ETL is probably a 6-8 week process.

For Z-Wave/Zigbee Certifications, this is usually done at the end of beta testing (sometimes we can get away with it around the last couple weeks of beta testing if we’re confident in the firmware) and this is normally a 6 week process.

Then production is a 3-4 week process and finally shipping is another month or so.

My best guess would be mid-December at best. I’ll let everyone know if we’re able to make up some time.

We may be able to make up time in the beta testing since we’re using our main manufacturer and a lot of the code is the same and their firmware guy is a wizard. The challenge is going to be the Associations and Zigbee Bindings and making sure they’re mapped correctly based on the button configuration. I know he’s been working on the firmware simultaneously, so who knows, maybe we can cut testing down to 3-4 weeks.

Thanks for the updates! You looking for any beta testers?

And here I thought the community would be the feature creeper always!

Project Update:

We received CEDIA samples and they look awesome! Really good 3D print.

Just a backstory real quick – the B2B company that we work with wanted these for CEDIA so they could show them off and while we couldn’t get tooling done on time, we got it pretty close via a 3D print and the firmware on the devices are very basic, so keep that in mind with the videos below. Once we get back from CEDIA (Sept 5-7), we should be finalizing tooling and onto firmware development (the real beast).

But I want to say I’m super proud of the hardware team on this one – they managed to pull off the hardest project (from a hardware standpoint) that I’ve ever worked on.

As you may know, we had a different manufacturer working on this initially and they couldn’t figure out how to meet all the requirements so we transitioned back to our main one and put them under a strict timeline and they delivered.

Not only that, but initially we were told that the 8-Button design wouldn’t allow for etching due to light leakage and other factors, but they managed to get it to work. In addition, we had a last minute request from the B2B partner (bc why not? Right @stephen.brown2 lol?) to get it so the text on the switch could be left-justified instead of center justified so that more words could be added to the paddle.

–

So, it’s my pleasure to share this bc I’m really excited for it.

Pics

Note: Some of the laser etching is off and the buttons look a little off, but in person it looks much better. I didn’t take the pics as they were sent straight to the B2B client:

Videos

Again, this is basic firmware – in the final switch, the LED indicators will be able to light up and be a different color than the words if you want.

Wow - This is great! There will be so many possibilities with this switch! I just can’t wait. ![]()

Has there been any specs released on these? How much load will these be able to handle? Or are they limited to lights only?

I originally pre ordered the first version in 2021 and haven’t really followed the revived version.

I expect the manufacturer would re-use the same dimmer circuitry design as the Red and Blue dimmers so it should have the same load capability as those.