It should be capable of being set as an End Device with a firmware change. Being set as a Router or End Device should be handled by the firmware residing on the RF module or the separate processor if it is not using the modules onboard processor.

Is there a FAQ or help page that can be set up for this issue? It’s impossible to follow 300+ continuing updates.

I don’t think I have a switch in the noted IEEE range, but one of my Blues is the only Zigbee device on my network that frequently seems to drop, and come back on randomly, even as it is in a room with another Zigbee router. LQI for both devices is always low (low 30s) in Z2mqtt.

How is this email going out? Did people enter info into a form, or does Inovelli know who purchased what IEEE?

Very confused new user here…

As of right now, the replacement form only applies if you have 94:34:xx and/or 38:5B:xx switches. So confirming the IEEE number on each of your switches needs to be your first step.

If a switch has one of those #s, then take a good picture of its QR code on the front of the switch – that picture (and the device’s IEEE) will need to be included in the replacement form.

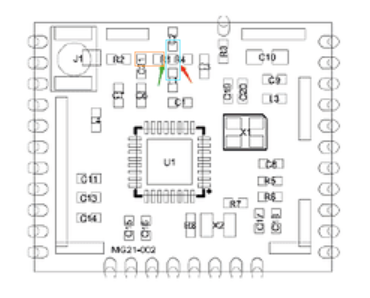

For anyone considering doing the DIY repair, I did some probing before modifying mine and it appears that a lot of the pads in the R1 area are common (see picture below). The pads circled in blue are common and the pads circled in orange are common, so all you need to do to get the quick and dirty (90% signal) fix is bridge the orange to the blue by any means. The first one I did was a giant nightmare solder blob that covered basically all the pads circled and the switch connects perfectly to my deconz stick in the basement. For reference I am using whatever solder tip came with my Hakko 888 iron, which is by no means a fine tip. The best way I was able to get it to be pretty was to get a tiny bit of solder on the tippy tip of the iron, and while perpendicular to the board give the spot where R1 is upposed to be a quick boop to bridge the pads. I was able to get about 5 done in an hour this way last night, the hardest part really is getting the plastic pins through the FETs.

I tried to get some pictures of my repairs but I do not have a camera with adequate zoom, however if anyone wants any pictures of the internals I would be happy to take some.

Good to know. I guess one of my concerns is what potential harm is there in bridging the pads together instead of moving the component?

I’ve also had good luck putting a solder ball in place, but it sounds like moving the resistor would be more ideal.

According to this post earlier in this thread you should still get 90% signal strength. My assumption is the resistor is part of an impedance matching network for the antenna. It just isn’t worth the effort for me to move the resistor.

The resistor is not for impedance matching, it should be just a 0 ohm jumper for switching the RF trace between the edge pad and the RF connector. By not removing R4 you leave a stub of a trace going the other way so there is a little bit of signal loss.

That makes more sense, I can pop that resistor off easily so ill start doing that in the future, its moving it that would be a pain.

Solder tweezers, if you can borrow or source, could make moving the resistor a little easier.

Ooh I wonder if I could double iron dual wield for a similar result

I would be very impressed if you could do that. I don’t think that’s reasonably possible, but I think you should totally prove me wrong. Lots of products out there, but they are not inexpensive.

For reference:

Cool, glad to know that the blue areas are connected. I tried to add a solder blob bridge at R1 and managed to bridge R4 to C2 and haven’t been able to clear it out.

Dude I did the same thing and thought I was screwed till I opened another switch and figured that out haha.

@Eric_Inovelli is “we won’t be taking the existing switches back” the official answer? I don’t want to start opening up and voiding warranties or returns on existing faulty switches if that will hurt me in the future

See previous post.

Have you measured by any chance if R4 is indeed a 0-Ohm resistor?

Then an easier 100% solution would be to remove R4 completely (clean up the pad with some wick) and short R1 pads via solder blob (instead of re-using the 0-Ohm resistor)…

From my testing it does appear to just be a jumper, ill confirm 110% later tonight if I have time. I basically did exactly this for my second 5 switches, just popped the resistor off with the iron and bridged the pads.

For those who have done the repair how have you gotten the plastic pushpins back in? I’ve done the soldering and am stuck on getting that part back together.

push the ball pin as far in as you can or take them apart and put them back together extended as far as possible, put them in, don’t forget the thermal stuff, try and line things up keep trying until you get it. - putting it back together is frustrating for sure.

I’m sure there is a better way but I used very fine tweezers and hold the base of the pin “ears” and find something sharp to press the middle pin back inward then squeeze the ears back together some and press through the holes