I did the first few one at a time. then like 2. then like 3 then like 6. Now at 17 complete. My final batch I am doing all 20 in parallel. Last night i disassembled 20 switches. Tonight maybe solder 20. And then slowly reassemble in small batches and install the same night.

In all honesty, I am probably 10-15 hours in for 17. I also bought a $50 led magnifier arm for my workbench. I ended up burning out my cheap soldering iron and bought another one. Same price point.

It is critical to separate the pin inner and outer. And then install. It is super finicky. I use needle nose pliers and some straight and curved electronics tweezers. I am using a $8 soldering iron from amazon.

My side hobby right now is building about a dozen WLED controllers with parts off of aliexpress. Historically I have jtaged xbox 360s, Motorola modems, and modded consoles dating back to the original xbox. Built every computer I have owned since about 12 years old.

The biggest tip I got from another forum member dan4. His tip on the separating the pins was game changing.

“”"I hear ya, those pegs are bastards. There is a little bit of a cheat though which works and still prevents paddle squish. Start by putting the zigbee board into its plastic housing and make sure it clicks in place. Then attach the power board to the zigbee board - attach the power board pins but don’t put in the plastic pins yet.

Separate the two plastic pins into two separate pieces - just pull them apart - so that you have one that looks like a thumb tack (the bottom piece) and the outside piece which the “sharp” side of the thumb tack goes through. Keep them separated for now.

Using a small piece of tweezers or coffee free hands, put the thumb tack piece through each plate with the “sharp” side facing up. After each one is in place push the metal plate down so that the pin can’t go anywhere. Once you have both thumb tacks in place put the thermal blanket over the pins.

Then insert the outside part of the plastic pieces into the holes in the metal plate. Put the assembled boards back in their power tray then while looking through the sides to align the pins and then press hard into place until they snap into place (this part is crucial, otherwise you will get a mushy paddle). Oh, and make sure that the antenna isn’t getting smushed.

Screw the rest together and you’re done!

I’ve managed to put them together both ways. The OEM method took me a good hour to get the pins together properly - whereas this way takes me about 5 minutes to disassemble, solder and re-attach. For what it’s worth I’m using a stock tip on the Hakko FX888D - you don’t have to be too accurate from what I can tell, as long as you bridge over to R1 you’re good.“”"

I am not 100% sure I have actually fixed them. As I never actually tested a un-fixed switch. Us canadian’s didn’t get the switches until well after the issue was found and reported on. But I still have 37 replacements coming. So I can always swap if I have issues in the future. A bit of a good thing. I also realized that I ordered 7 too few switches. I’m going to order 5 of the fan switches when they become available.

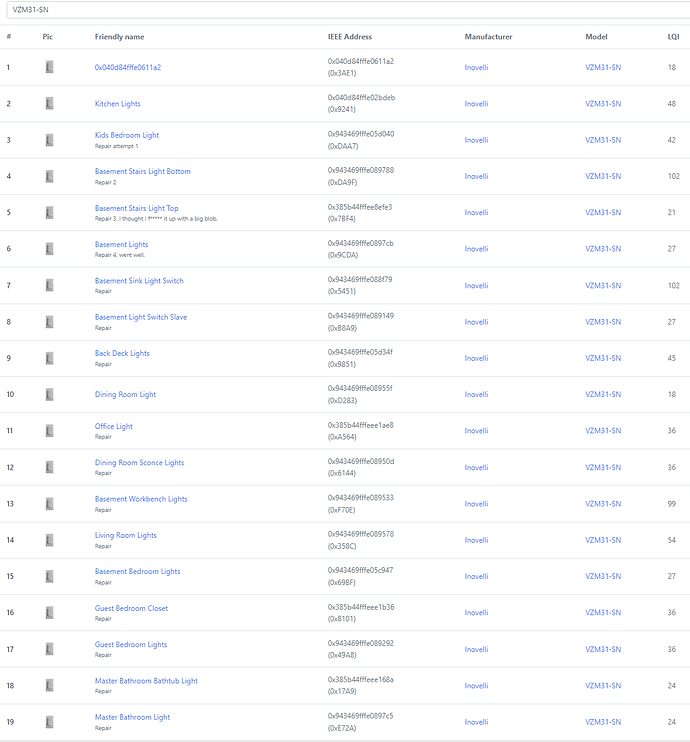

You can see the LQI of my workbench light switch which is immediately next to my home assistant raspberry pi is over 100. Everything else is progressively further out. My house is wood frame. 2 floors and a basement. And only 900sqft per floor. So I wonder if I did properly fix all of them.

Regards,

Aaron